Market gap plant design

Computer Aided Planning (CAP): Turnkey plants are often planned by several teams using CAD, CAE, ECAD and ERP systems: The lack of coherence complicates coordination, triggers many change loops and extends project times. The planning capacity of specialists is limited. Despite high demand and available components, the planning process slows down the growth of many manufacturers. These companies are urgently seeking a software environment for the efficient development of modular plants, for example in the areas of painting, finishing, assembly or logistics.

Computer Aided Planning & Engineering

Now the good news: With Computer Aided Planning (CAP) from Perspectix, large and complex systems such as distribution centers, filling stations or washing plants can be configured from parameterized catalog elements. In the process, companies save up to 50 percent of the planning effort. Once the plant is up and running, links to the original CAD models provide further synergy effects. That's what we call automatic plant configuration!

Configuration in the hall environment

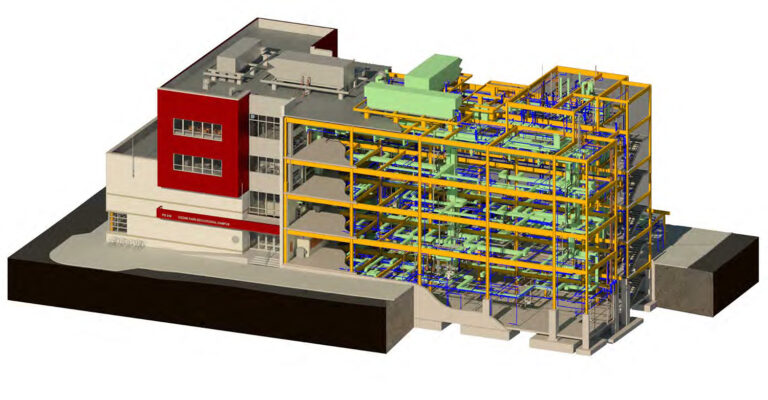

Computer Aided Planning (CAP) allows complex plants to be configured in hall-sized dimensions. In the context of 3D building data, collision-free plants are created on any number of floors, layers or levels. The plant components can be provided with more than 100 parameters and links. They are then placed in the imported hall environment in Building Information Modeling (BIM) IFC format using drag and drop.

Parametric plant configuration

Integration of machines, lines, piping

Functional units can be linked associatively and reviewed when changes are made. When planning in one section of a building, users recognize any effects on other areas. External objects, such as machines and packaging machines, carton presses or palletizers can be integrated as required. All connections and lines are taken into account.

Plant planning by multifunctional teams

To speed up development, up to 100 employees can edit a plant. The objects and areas of a plant configuration can be locked or released for editing as desired. This makes it easy for large teams to work together on a model.

Catalogs with 3D components

Like the product configuration, the plant configuration of the P'X Industry Solution is also based on catalogs that are developed together with the customer from CAD models. Product logic and parametrics are mapped in sets of rules that ensure fast and error-free product variants.

Comprehensive documentation

All documents such as offers, parts lists, 3D illustrations, assembly and installation instructions can be individually adapted and automatically output. As a result, the entire process is digitized, from the recording of requirements, configuration, pricing and quotation generation to automated variant design and installation planning, right through to spare parts management.

Computer Aided Planning: Our customers achieve these benefits

Up to

Faster configuration of customer-specific systems in distributed teams

Up to

Less planning effort due to parametric plant configuration

Up to

Lower error rate than in conventional processes

Up to

Fewer queries and ambiguities due to 3D representations and plans

Up to

Less design effort during realization

System configuration: What our users report

Bosch-Rexroth user report

Since 2007, Bosch Rexroth has been offering its extensive range of assembly technology products via a project planning platform based on the P'X Industry Solution in order to achieve shorter delivery times and higher customer satisfaction. With a web configurator also developed by Perspectix, the benefits have been extended even further.

CAP&E: Fünf wichtige Vorteile der parametrischen Anlagenkonfiguration

For many plant engineers, the real key to business performance is not production, but planning, design and tuning. Here's what innovation leaders are doing differently: Computer Aided Planning & Engineering (CAP&E) of industrial plants with Perspectix's P'X Industry Solution opens up huge efficiency gains. Read here how distributed teams create virtual plants from parameterized components in large halls.

Wie Hersteller sich auf BIM einstellen (sollten)

Building Information Modeling (BIM)

is changing traditional working methods and posing complex challenges. But in the digital transformation, the method is gaining acceptance among architects, planners, contractors and developers.

Digitization means seamless integration

System configuration: The close integration of the P'X Industry Solution with ERP, CAD, PLM and CRM limits the effort and increases the benefits for the company. This is why Perspectix relies on global standards, open architecture and individual interfaces.

Let's talk about your project!

Do you have questions about our offer or a specific project? We are happy to be there for you.

Call us or request an appointment for an online meeting!

Let's talk about your project!

Do you have questions about our offer or a specific project? We are happy to be there for you.

Call us or request an appointment for an online meeting!